Industrial IoT in Smart Manufacturing

Since the first industrial revolution new methods of technology continue to improve the efficiency of manufacturing processes. Once the computer was introduced, digital technology began to play a vital role in industrial automation. This era became known as the industry 3.0 revolution. Now industry 4.0 is the new industrial revolution which introduces the smart factory, including smart manufacturing, artificial intelligence (AI) and autonomous systems.

How is wireless connectivity used in industry 4.0?

In any smart factory, a reliable IoT connectivity solution is key to an efficient system. The IoT devices must be always online and fully operational. Even a few minutes of down time can cost some companies thousands of dollars.

Ready to Get Started?

Datablaze can provide connectivity and IoT solutions for your smart factory.

Smart Factory IoT Use Cases

Smart factory applications can be practically endless, but here are just a few examples of how a manufacturer can implement industry 4.0 technology.

Rapid Prototyping

By gathering data through sensors on the production floor, manufacturers can make better decisions before going into full production. Sensors on products can also be implemented in the field to gather data in real-life scenarios. Collecting this data in real-time can help engineers make quick changes for a more efficient product.

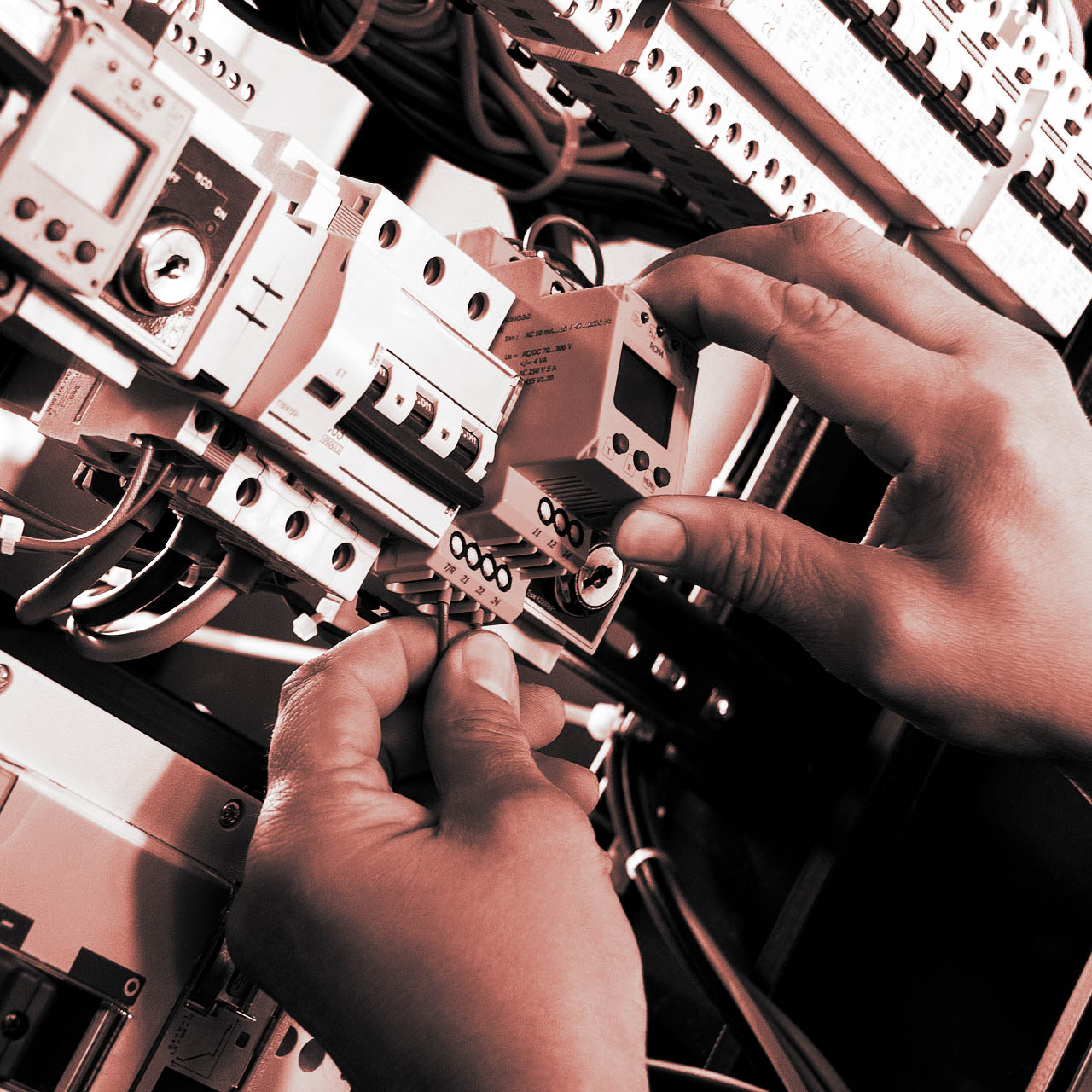

Digital Quality Control

With machinery already connected to cloud platforms, storing data such as temperature and pressure, is easier to digitally track in production batches. This technology can significantly help reduce poor quality product from reaching the consumer and reduce the need of costly recalls.

Predictive Maintenance

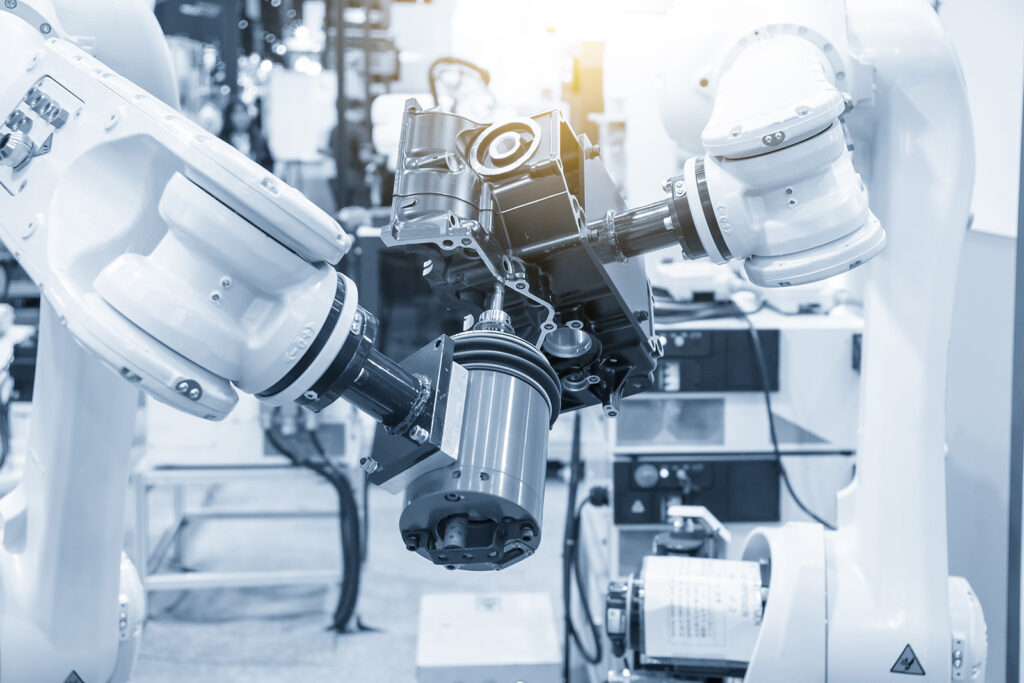

Through sensors and connectivity machines can collect and analyze data to determine if a potential problem may occur. The real-time data and cloud-based analytics can help engineers and maintenance crew spot inefficiencies with machinery allowing them to replace components before they fail.

Predictive Maintenance Reporting IoT Sensors Minimize Downtime

Warehouse Management

Knowing where your inventory is and an efficient method to stock and pick inventory has always been a challenge for warehouse management. In a smart warehouse IIoT solutions use sensors to give real-time locations, quantities, and temperatures. Autonomous robots can pick and pack an order, all without any human interaction.